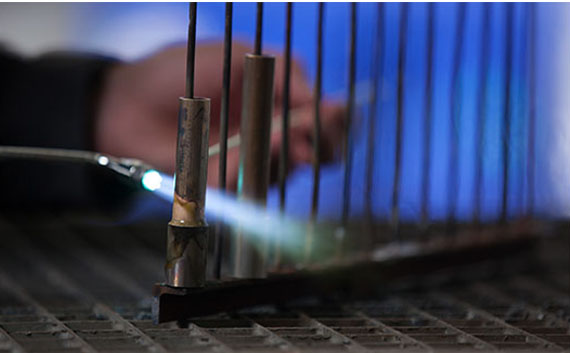

GRIFLAM® flame soldering technology – our solution for your soldering requirements. The widest variety of hard and soft soldering tasks can be safely mastered with our GRIFLAM® flame soldering torches. This is a joining process with the additional use of a filler material, the solder.

Your advantages:

- Heat input to the exact spot

- Individual consultancy and layout

- Layout of the complete gas supply system

- Application technicians for tests, commissioning and service

Areas of application:

- Sanitary equipment

- Cooling and air conditioning

- Engineering

- Pipeline construction

Contact

Messer Cutting Systems (China) Ltd.

528 Nanbang Road

Kunshan 215300

Jiangsu Province

China

Access to the component itself, the use of special fluxes as well as the use of special materials make precisely defined demands on the soldering torch. The determination of the torch power required, the appropriate flame shape of the torch construction shape can then often only be established in our GRIFLAM® test laboratory.

Flame Soldering can be done by torches suitable for acetylene or hydrogen in combination with either oxygen, compressed air or siphoned air. Furthermore, torches for slow burning gases like propane, methane, MAPP or GRIESON in combination with either oxygen, compressed air or siphoned air are common. Those kind of torches are usually line torches, heating inserts, forked torches or ring torches. Moreover, special lengths and designs can be supplied on request.

Learn More

Solution Modules

Messer Cutting Systems is the solution provider for the metalworking industry. In addition to cutting machines and oxyfuel technology, we offer software solutions, spare parts and a wide range of services.

We are sure that we will find the right solution for your individual requirements. Contact us, we will reply to you as fast as possible.