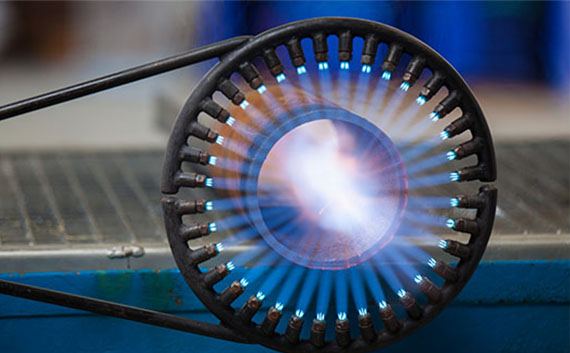

GRIFLAM® pipe heating technology – our solution for your pipe heating requirements. With our diverse pipe heating torches, heat can be applied targeted to the areas of the components you require. The process is especially suitable for pre-heating and post-heating when welding and cutting, for shrinking processes and for forming applications.

Our pipe heating torches are available in numerous standard sizes and made with special component shapes to suit customer requirements and product geometries. We differentiate here between stationary applications with pipes which can be rotated and ring torches for pipes which cannot be rotated. These can also be combined with an automatic control.

Your advantages:

- Targeted heat input

- Individual geometries

- Fully automatic solutions

- Individual consultancy and planning

- Layout of the complete gas supply system

- Application technicians for tests, commissioning and service

Areas of application:

- Steel mills

- Engineering

- Steel construction

- Plant construction

- Shipbuilding

Contact

Messer Cutting Systems (China) Ltd.

Messer Cutting Systems (Suzhou) Ltd.

Room 3, 528 Nanbang Road

Kunshan 215300

Jiangsu Province

P.R. China

Pipe Heating is usually done by torches suitable for acetylene in combination with either oxygen or compressed air. Furthermore, torches for slow burning gases like propane, methane or MAPP in combination with either oxygen or compressed air are common. Beside standard hand ring torches, also semi or fully automatic solutions are possible. Moreover, special lengths and designs can be supplied on request.

Solution Modules

Messer Cutting Systems is the solution provider for the metalworking industry. In addition to cutting machines and oxyfuel technology, we offer software solutions, spare parts and a wide range of services.

We are sure that we will find the right solution for your individual requirements. Contact us, we will reply to you as fast as possible.